Sewer Rehabilitation by CIPP

Project background

Utilities Kingston cleans and inspects the sanitary sewer pipe network in the City of Kingston on a 12-year cycle. As a result of these inspections, pipes are identified that require rehabilitation or reconstruction. Typically, if defects are caught early enough, the pipe can be rehabilitated proactively with a trenchless (no-dig) method called 'cured-in-place pipe' or CIPP for short.

CIPP is a rehabilitation method that involves pulling or inverting a resin-saturated liner into the sewer, pressurizing it so it expands and adheres to the host pipe, and then curing the resin with hot water, steam or UV light. Once cured, the liner itself forms new pipe inside the original defective host pipe.

The CIPP method is well-established and more cost-effective compared to traditional pipe excavation and replacement. It ensures that the infrastructure will maintain an adequate level of service for well over 50 years into the future. It also has the benefits of eliminating joints and providing a complete seal against inflow and infiltration of groundwater. More importantly, for residents, it is a much quicker process with only minor inconveniences in comparison to traditional open-cut pipe replacement.

Inspection data is reviewed for suitability of pipes for lining. Once pipes are identified to a) require rehabilitation, and b) suitable for CIPP technology, they can be added to this program, ideally in an area-by-area approach for rehabilitation.

Areas where CIPP Rehabilitation Method has been implemented since 2020:

- Kingscourt neighbourhood

- Strathcona Park

- Grenville Park

- Hillendale

- Calvin Park

- Polson Park

- St. Remy Place

- Days Road Collector

- Rideau Heights Collector

- North Harbourfront Interceptor

- Williamsville

- Kingstown

- Kingscourt-Rideau

Services affected

Planning

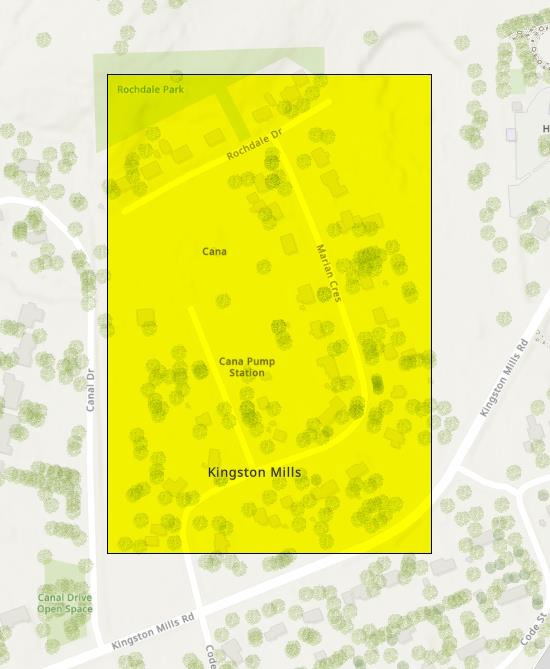

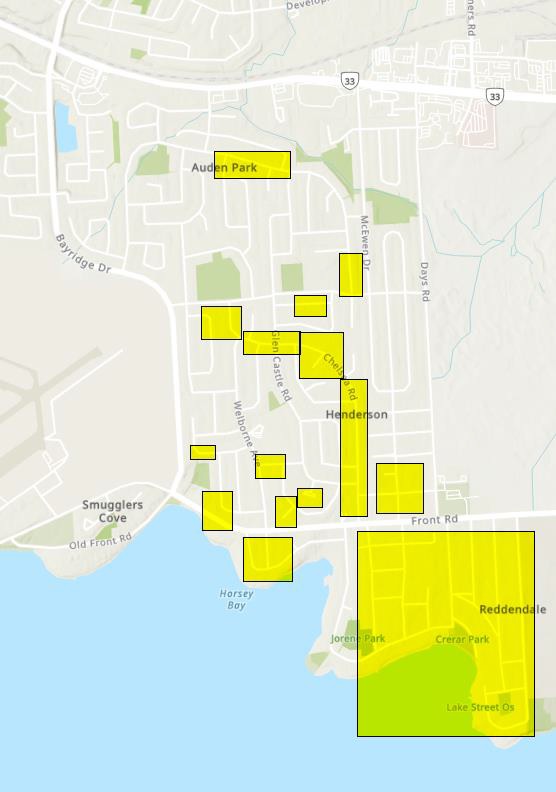

The 2025 program is planned to complete approximately 8000 meters of sewer pipes including the areas bellow:

| Bishop St | Lakeview Ave |

| Cana Blvd | Marian Cres |

| Chelsea Rd | Montgomery Blvd |

| Cranbrook St | Olive Cres |

| Crerar Blvd | Park Cres |

| Crescent Dr | Point Cres |

| Dale St | Redden St |

| Front Rd | Rochdale Cres |

| Gordon St | Sinclair St |

| Jorene Dr | Strathaven Pl |

| Keyes St | Sunny Acres Rd |

| Lakeland Point Dr | Wartman Ave |

| Lakeshore Blvd | Windsor St |

Please note - if your home or property will be affected by this project, you will receive multiple notifications hand-delivered by our contractor to notify you when the work will happen, and anything you may need to do to prepare, or not do, during this process. Contact names, phone numbers and emails will be provided on notices, and are also available at the bottom of this webpage.

*Areas may be reduced, or additional areas may be added as other priorities of sewer lines are identified.

Design and Construction

The elements of construction include the following:

- Video inspection by CCTV. Videos are completed at minimum three times for the sewer lining process, and include V1 (pre-works inspection), V2 (post-pipe preparation inspection) and V3 (post-CIPP or final inspection). This is a simple process with no risk or disruption in service to customers. A mobile camera is run from one maintenance hole to the next.

- Pipe Preparation. Preparation of pipes for lining may include the following tasks:

- Cleaning. The pipe is cleaned with a high-pressure jet to remove debris, grease and other materials in the sewer.

- Reaming. If roots and other hard-deposits are found, reaming of these materials will be required using a robotic cutter.

- Void filling. If significant voids are present, they may need to be filled robotically prior to lining.

- Spot Digs. If the majority of the host pipe is suitable for lining but one or two significant defects are identified that cannot be lined, spot repairs by digging may be required. Lining remains cost effective even if one or two digs are required, but not much more than that.

- The pipe preparation process does not result in an interruption to service.

- CIPP Lining. The lining process involves multiple steps that typically happen over the course of a single day (12 hour period), as follows:

- Insertion of liner. A resin-saturated liner is delivered to site, and installed into the host pipe by pulling it in place or inversion. This point begins the process that temporarily reduces service to customers.

- Curing the liner. The liner is cured with heat, either using hot water, steam, or UV light.

- Reinstatement of service. Once cured, the new CIPP pipe ends are cut open, and a robotic cutter is inserted into the liner to cut open service connections. After this is complete, the sewer is back into regular service. This typically takes 4-6 hours.

Schedule and Project Downloads

Construction is Complete for 2025

Utilities Kingston notice to customers

Residential notice of construction Cana

Residential notice of construction Lakeside

Insituform notice to customers

- Last updated: July 10th, 2025

We recognize that the upcoming construction work in your neighbourhood may bring some disruptions and inconvenience. We sincerely thank you in advance for your understanding and patience as we undertake this project.

Contacts

If at any time you experience an emergency you feel is related to this project, please touch base with the Contractor immediately. If this is a less urgent matter pertaining to the contract, please touch base with Utilities Kingston staff member.

Rachel Quittkat, C.E.T.

Engineering Technologist

85 Lappan's Lane

Kingston, ON K7L 4X7

Office: 613-546-1181, extension 2242

Email: rtquittkat@utilitieskingston.com

Laura Segura Serrano, Ph. D (she/her)

Project Manager

85 Lappan's Lane

Kingston, ON K7L 4X7

Office: 613-546-1181, extension 2217

Email: lseguraserrano@utilitieskingston.com

Sinan Omari

Sr. Project Manager

3 Burford Road

Hamilton, ON L8E 3C6

Cell: 289-439-5683

Office: 905-561-1778, extension 480227

Email: somari@insituform.com