Where clean water begins: Inside Cataraqui Bay Wastewater Treatment Plant

Nestled along the shores of Cataraqui Bay and Sand Bay, our wastewater treatment plant plays a vital role in keeping our community and environment healthy—quietly working behind the scenes every single day.

Our recent upgrades are officially complete, and we couldn’t be more excited. With a 40% boost in capacity and some serious technology upgrades behind the scenes, we’re now treating wastewater more efficiently—and more effectively—than ever before.

From powerful new filtration systems to smarter ways of managing waste, these improvements help keep our local waterways cleaner and our community healthier. It’s all part of building a stronger, more sustainable future for everyone who calls this region home.

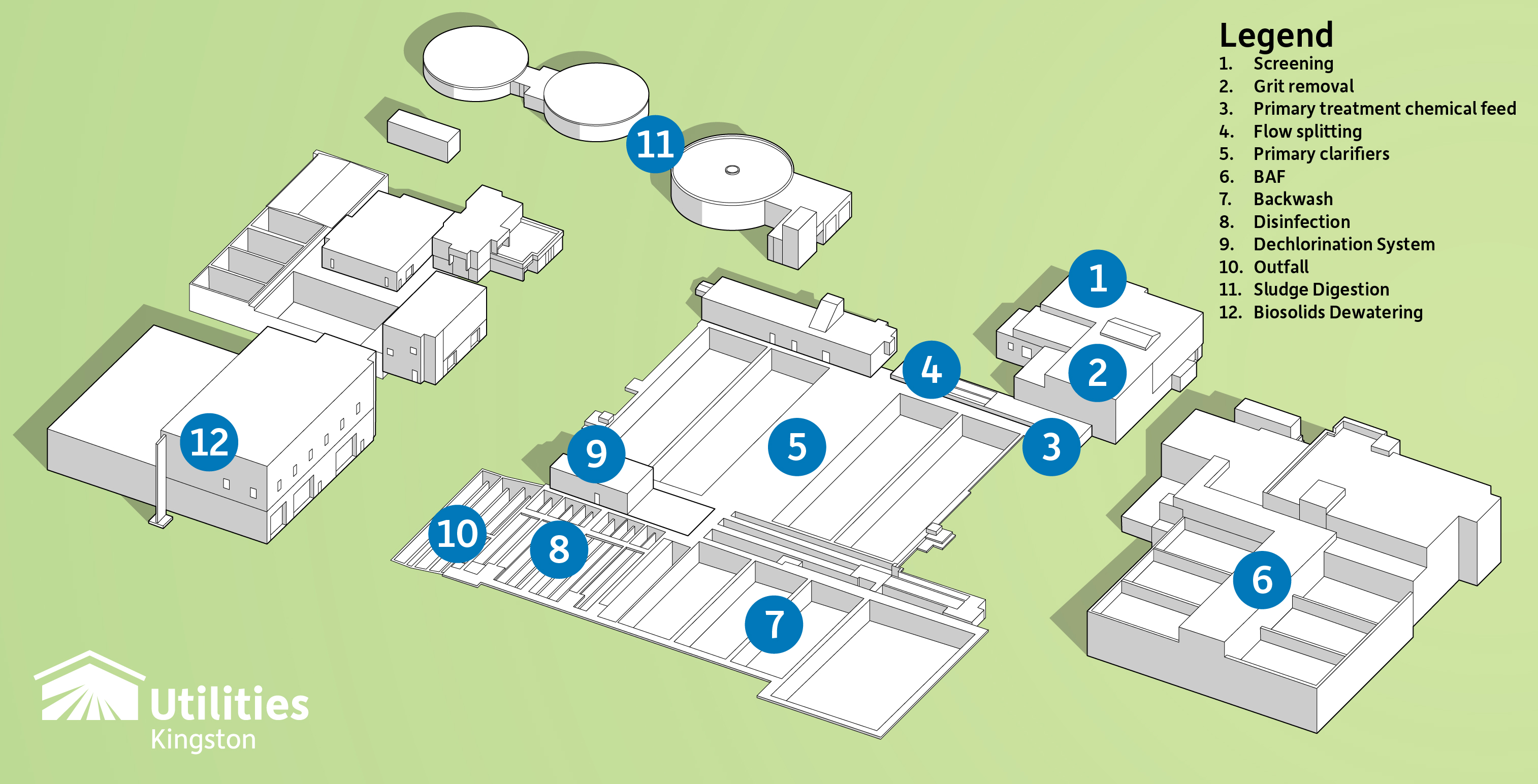

Explore the Cat Bay facility

| Facility | Facility description |

|---|---|

| Screening |

The first step in treating wastewater is screening, where large items like wood, rags, and plastics are removed from the water. There are two fine screens with 6 mm holes, each placed in a 2-meter-wide channel. These catch the debris, which is then washed, compacted, and sent to a disposal bin. A third channel has a manual coarse screen for backup, and a fourth channel with an overflow weir is used only in emergencies to bypass the main screens. |

| Grit removal |

The second step in preliminary treatment is grit removal. In this stage, heavier materials like sand and gravel settle to the bottom, while lighter organic matter stays in the water and moves on to the next step. This system includes two vortex grit tanks, each with a paddle mixer and a slurry pump. The settled grit is pumped into two grit classifiers, which remove the water from the slurry and send the dry grit to disposal bins. |

| Primary Treatment |

Right after the grit tanks, a chemical called ferric chloride is added to the wastewater. This helps remove phosphorus and suspended solids more effectively. The system includes two storage tanks and two feed pumps that add the chemical based on the flow of the water. |

| Flow splitting |

After screening, grit removal, and chemical addition, the wastewater flows into a channel that splits into two parshall flumes, which measure the flow. From there, the flow is divided into a main channel that feeds four identical primary clarifiers. Air is added to the incoming channel using centrifugal blowers to prevent solids from settling too early. |

| Primary clarifiers |

The primary treatment system includes four primary clarifiers. In these tanks, heavier organic materials settle to the bottom by gravity, forming a sludge blanket. Collector flights move the sludge to a hopper at the end of each tank. At the same time, surface skimmers remove floating scum and grease near the surface. Both the settled sludge and the removed scum are then pumped to digestion facilities for further treatment. |

| Biological aerated filter |

After primary treatment, wastewater is pumped through the Primary Effluent Pumping Station (PEPS) to the Biological Aerated Filter (BAF). An alkalinity solution is added after pumping to help maintain proper pH for treatment. The BAF has six filter cells filled with two types of media—polystyrene beads and plastic disks—that support microorganisms and help filter solids. Air is added to help these microorganisms grow. They remove organic matter, ammonia, and phosphorus from the water as it moves upward through the filters. |

| Backwash |

The biological filters need regular backwashing to clean off excess biomass. The backwash water is stored temporarily in two tanks. The facility can either add this backwash water back to the primary inlet or send it to two gravity thickeners. Alum is added to help solids settle in the thickeners. The settled solids are pumped to a sludge thickening facility, which uses holding tanks, rotating drum thickeners, and a polymer system to concentrate the solids before sending them to the primary digester. The clear liquid from this process is returned to the primary inlet channel. |

| Disinfection |

After the BAF, the water flows through a parshall flume to measure the flow before entering the chlorine contact tanks. A chlorine gas system adds chlorine for disinfection. It includes two sets of chlorinators that dose the water to ensure the water is properly disinfected. Two chlorine contact tanks provide enough time for the chlorine to work before the water moves on. |

| Decholorination System |

Before the treated water is released into Lake Ontario, chlorine is removed using a dechlorination system with calcium thiosulphate. The system includes one storage tank and two metering pumps that add the chemical right after the final flow meter in the outfall chamber. |

| Outfall |

After dechlorination, the treated water is released into Lake Ontario through two outfall pipes, one 1500 mm and one 900 mm in diameter. At the end of each pipe, 17 diffusers spread the water 25 meters offshore and 16 meters below the surface. |

| Sludge disgestion |

Raw sludge, grease, scum, and thickened backwash residuals are pumped to the primary digester throughout the day. The digestion facility has two anaerobic digesters with shared gas systems, a sludge holding tank, pumps, and a heat exchanger. The digesters mix sludge and gas to break down waste, producing methane-rich gas and biosolids. The methane gas fuels the boiler, which provides heat for digestion and the facility’s buildings. The biosolids are dewatered and, when conditions allow, used as fertilizer and soil conditioner on farms. |

| Biosolids Dewatering |

Liquid biosolids are pumped into centrifuges where polymer is added to help solids stick together. The centrifuge separates solids (called cake) from liquid (called centrate). The cake, about 24% solids, is stored, while the centrate is returned to the start of treatment. |

History of Cat Bay

- The west-end plant was constructed in 1962 and went through its last major upgrade in 2002.

- The current upgrades were identified as a City of Kingston priority in the 2010 Sewage Infrastructure Master Plan.

- The most recent upgrades to the plant increased capacity from 38,800 to 55,000 cubic meters per day to meet projected population growth. Did you know?

Our in-house knowledge to customize software for our systems helps us operate efficiently. It also means that when we respond to trouble calls, we know the problem and can get it up and running more quickly.

The multi-utility model has allowed us to build an in-house, specialized programming team that is recognized in our industries. Ontario municipalities reach out to learn about our innovations, such as the widely-recognized sewer overflow sensors and custom dashboards at treatment plants. Our programming team works closely with our treatment operators to customize the dashboard that allows them to monitor and control treatment operations.

To give you an idea of the magnitude of this task: the largest PLC at the plant is programmed with FIFTY THOUSAND lines of code, controlling 325 devices.