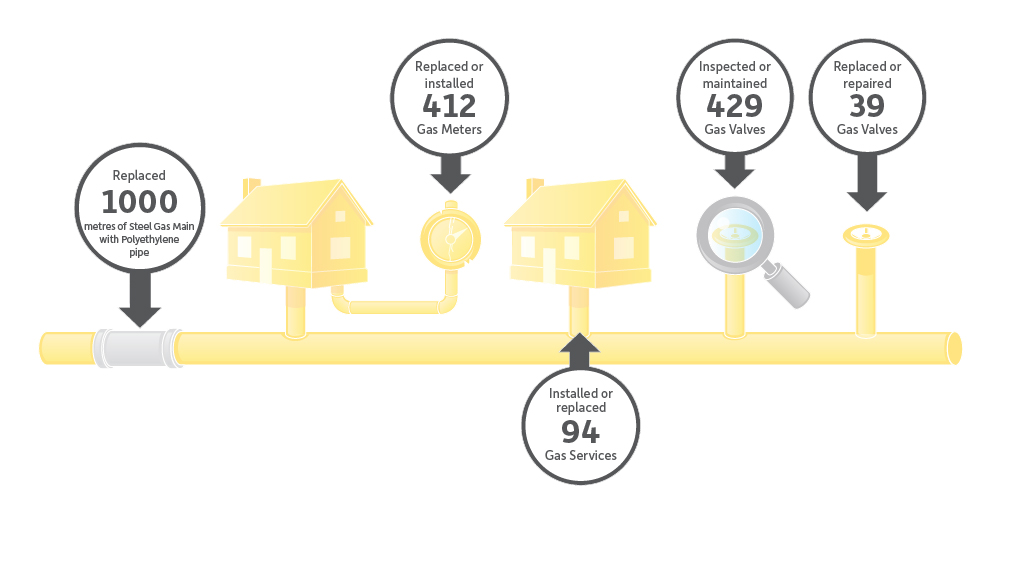

2020 Achievements

Click to enlarge

Click to enlarge

What's the context?

We've provided data on our achievements in 2020. If you're looking for additional context on how much overall infrastructure we maintain, check out our overview infographics.

412 gas meters replaced is out of 15,000 gas meters in the municipal gas distribution system, which have reached their end of life, as determined by Measurement Canada.

Internal Resources for New Gas Main Installs

During 2020, Utilities Kingston brought in house some of the work to install new gas mains. During the year, we installed approximately one kilometre of new gas main in the area of Kingscourt Avenue and Nelson Street and 2.5 kilometres gas main for a new Conacher Drive development.

In-house Gas Service Installations Continue

For the third year, we continued our efforts to install new gas services using in-house resources, replacing or installing 94 gas services. Our crews worked diligently to provide timely installations.

Our installation crew ensures excellent quality of work. This activity allows our team to continually assess the condition of underground assets, as we expose and work on pipes throughout the city. It exposes our staff members to all aspects of gas construction work.

Gas Valve Maintenance Program

Utilities Kingston maintains over 1,400 mainline gas valves. The gas valve maintenance program helps to ensure the integrity of the municipal gas distribution system.

In 2020, we inspected or maintained 429 valves, an increase over 2019, focusing on high pressure and steel gas mains, and priority valves for schools, hospitals and construction sites.

More Efficient Natural Gas Line Heaters for the Municipal System

In 2019, Utilities Kingston replaced the natural gas line heaters at two regulating stations with more efficient Cold Weather Technologies Natural Gas Line Heaters.

While, in 2020, our staff worked through maintenance issues, we realized energy savings of approximately $200,000. We will continue to resolve mechanical issues in 2021.

We anticipate that this upgrade will reduce energy consumption to heat natural gas by 50 per cent. This is expected to conserve over 300,000 cubic metres of natural gas annually and reduce carbon emissions by 600 tonnes, equivalent to 130 cars removed.

Training: Competency Assessment Program

Staff training and competency continued to be a key focus. We identified training and assessment requirements under the Competency Assessment Program. All new employees involved in gas operations took part in the Technical Standards & Safety Authority (TSSA) Gas Pipeline Inspectors Certification.

Ensuring Gas Safety

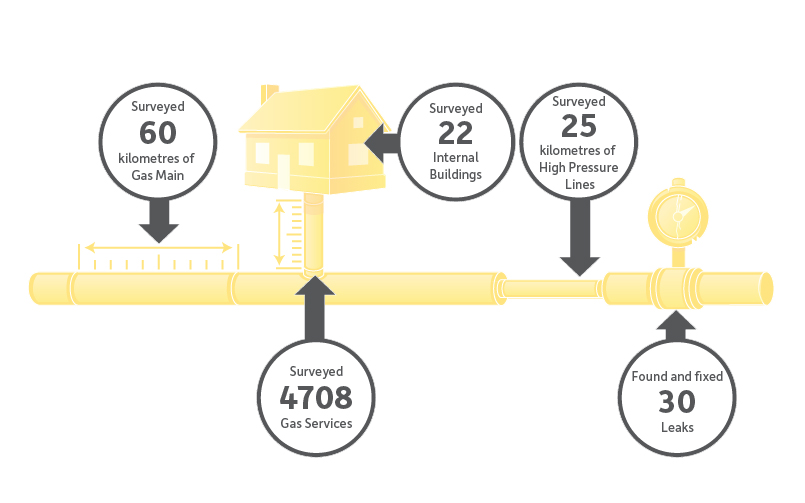

As part of maintaining the integrity of the natural gas system, on an annual basis we inspect over 20 per cent of the infrastructure for leaks.

Overall, we maintain 261 kilometres of gas main and the other assets described in our natural gas overview infographic. Here's what we inspected in 2020:

Click to enlarge

Click to enlarge

Regulation and Legislation

Reporting System Damage

Ontario Regulation 210/01, Oil And Gas Pipeline Systems, requires that Utilities Kingston reports when there has been damage to the system that results in a gas leak. In 2020, there were a total of 13 occurrences, compared to 11 in 2018 and 18 in 2019.

Distributors Audit

In 2020, the TSSA conducted its five-year distributors audit to determine compliance with O. Reg. 212/01, the Code Adoption Document and applicable codes, with a focus on the Distributions Safety Integrity Management Program (DSIMP).

While 11 recommendations were provided, the results of the audit where good, with no major infractions:

- Three recommendations for additional field review and modification.

- Nine recommendations for changes to DSIMP, to align more closely with the new version of the CSA Z662 Standards.

The TSSA has approved our plan to implement the recommendations, none of which will result in major financial implications.

Audit of Customer Appliances

As part of a TSSA audit, mandated under the Electricity and Gas Inspection Act, we conducted 493 inspections of customer-owned appliances, piping and fittings, and identified 194 hazards. Property owners were advised on what to do next, helping to improve occupant safety.

To help ensure health and safety during the pandemic, we limited this work to reduce entry into customer homes.

Cathodic Protection

Cathodic protection is used to control the corrosion of steel piping systems and extend their useful, safe life. Utilities Kingston operates 24 kilometres high pressure and 73 kilometres intermediate pressure steel gas mains.

To improve monitoring, in 2020, our crews and contracted services installed 12 test stations. Seven anode banks and 14 individual anodes, to total 28 anodes, where also installed in 2021.

Additionally, we contracted an accredited consultant to provide testing and recommendations to strengthen our findings. These will be implemented in 2021.

Legal Requirements of Gas Meters

As determined by Measurement Canada, and in accordance with the Electricity and Gas Inspection Act, every year we send a sample number of gas meters to verify accuracy and that the meters conform to legal requirements.

In 2020, we replaced 412 gas meters for this purpose. While this was less than planned for the year, it represented a major accomplishment for our team, due to the challenges of COVID-19, as this work requires our gas technician to enter customer premises.

Gas meters must be verified and reverified within appropriate periods, established on the basis of their stability of performance, application and usage. Measurement Canada determines how meters are selected for verification. This is based on criteria that include age, size and manufacturer. Meters are typically verified and reverified every 7 to 10 years.